How are Barcode & RFID Inventory System Innovating Businesses?

To ace the world of business, it’s important to incorporate technologies like barcode and RFID. If you are an entrepreneur who is unsure of how to get started with these technologies, this article will be of great help to you. Scroll till the end to explore everything.

What are Barcodes?

Barcodes are visual representations of data that consist of a series of parallel lines, rectangles, or dots varying in width and spacing. They are machine-readable and used for automatic identification and tracking of items. Barcodes encode information such as product numbers, serial numbers, or batch numbers in a format that can be quickly scanned and interpreted by barcode scanners or cameras. Common types of barcodes include UPC (Universal Product Code), EAN (European Article Number), Code 39, and Code 128. Barcodes are widely used in retail, logistics, healthcare, and manufacturing industries to improve efficiency, accuracy, and inventory control processes.

What is RFID Inventory System?

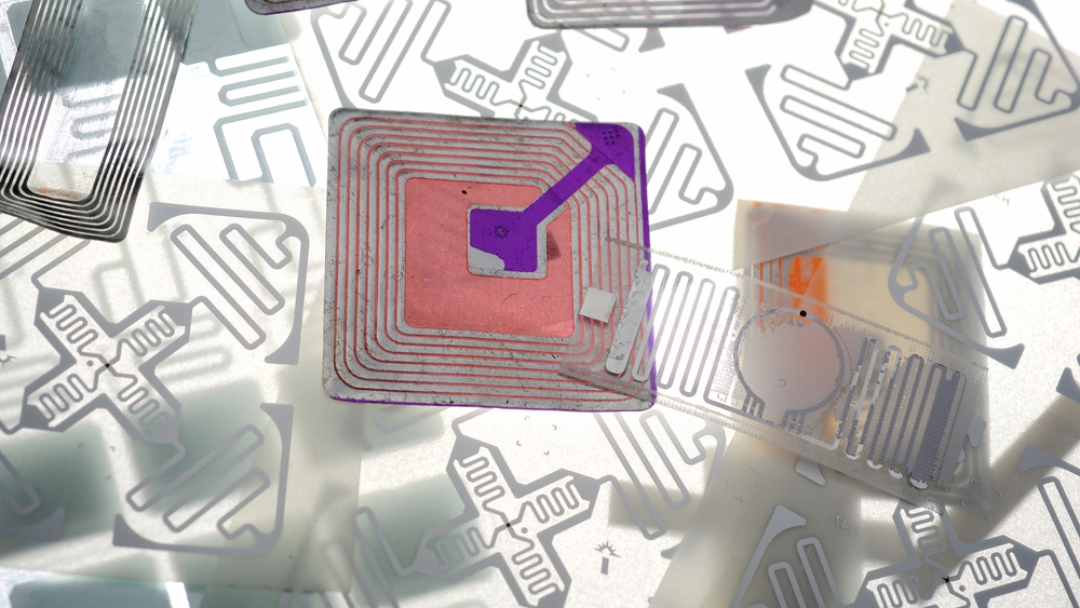

RFID (Radio Frequency Identification) inventory systems use radio waves to automatically identify and track tags attached to objects. Each RFID tag contains a unique identifier and potentially other data, such as product details or location information. Unlike barcodes, RFID does not require line-of-sight scanning; tags can be read remotely within a range from a few centimeters to several meters, depending on the frequency used.

RFID systems consist of RFID tags, RFID readers (or scanners), and a backend database or system for storing and processing the data collected. This technology is used in various industries for inventory management, asset tracking, supply chain management, and logistics, providing real-time visibility and automation capabilities.

Role of Barcodes in Innovating Business:

Barcodes play a crucial role in innovating business operations by enhancing efficiency, accuracy, and overall productivity in several key ways:

1) Automated Data Entry: Barcodes automate the process of data entry by encoding information such as product details, prices, and batch numbers into a scannable format. This reduces human error associated with manual data entry and speeds up operations.

2) Inventory Management: Barcodes enable real-time tracking of inventory throughout the supply chain. This improves inventory accuracy, reduces stockouts, and ensures optimal stock levels, leading to cost savings and improved customer satisfaction.

3) Operational Efficiency: By integrating with inventory management systems, barcodes streamline operations such as receiving goods, picking orders, and conducting audits. This efficiency boost translates into lower operational costs and faster throughput times.

4) Improved Decision-Making: Access to accurate and timely inventory data allows businesses to make informed decisions regarding purchasing, stocking, and replenishment. This enhances forecasting accuracy and strategic planning.

5) Customer Service: Barcodes facilitate faster checkout processes in retail settings, reducing waiting times for customers and improving overall service levels. They also enable better traceability of products, enhancing customer trust and satisfaction.

6) Compliance and Traceability: Barcodes help businesses comply with regulatory requirements by providing accurate tracking of products through their lifecycle. This is particularly important in industries like pharmaceuticals and food where safety and quality standards are stringent.

In summary, barcodes innovate business operations by optimizing inventory management, enhancing operational efficiency, improving decision-making processes, and ultimately driving growth and competitiveness in today’s market.

Role of RFID in Innovating business:

RFID (Radio Frequency Identification) technology plays a pivotal role in innovating business operations by providing advanced capabilities that enhance efficiency, visibility, and automation across various industries:

1) Real-time Tracking and Visibility: RFID enables businesses to track items in real-time without requiring line-of-sight, unlike traditional barcodes. This capability allows for continuous monitoring of inventory, assets, and shipments throughout the supply chain, improving logistics management and reducing losses.

2) Inventory Management: RFID automates inventory counts and updates, streamlining processes such as receiving, stocking, and cycle counting. This automation reduces labor costs, minimizes errors, and ensures accurate inventory levels, thereby optimizing supply chain operations.

3) Enhanced Data Accuracy: RFID tags can store more information than barcodes, including unique identifiers, product details, expiration dates, and manufacturing batch numbers. This detailed data improves accuracy in inventory management, quality control, and compliance with regulatory requirements.

4) Improved Operational Efficiency: By automating tasks such as asset tracking, RFID frees up employees from manual processes, allowing them to focus on higher-value activities. This efficiency boost leads to faster throughput times, reduced operational costs, and enhanced overall productivity.

5) Supply Chain Optimization: RFID technology facilitates better decision-making through real-time data insights into inventory levels, location tracking, and order fulfillment status. This capability enables businesses to optimize supply chain processes, improve demand forecasting, and respond more swiftly to market fluctuations.

6) Enhanced Customer Experience: RFID enables faster and more accurate order fulfillment, reducing lead times and ensuring product availability. This contributes to improved customer satisfaction and loyalty by meeting expectations for timely delivery and reliable service.

7) Security and Traceability: RFID tags can incorporate security features and enable better traceability of products, enhancing supply chain security and reducing the risk of counterfeiting or theft.

Hence, RFID technology drives innovation in businesses by revolutionising inventory management, enhancing operational efficiency, providing real-time visibility across supply chains, and ultimately supporting growth and competitiveness in the global marketplace.

SUMMING UP

Barcode and RFID inventory systems innovate businesses by enhancing efficiency and accuracy in inventory management. Barcodes streamline data entry, reducing errors and enabling real-time tracking from receipt to distribution. They integrate seamlessly with existing systems, optimizing operations and lowering costs. RFID systems offer real-time item tracking without line-of-sight constraints, automating inventory updates and improving visibility across supply chains. This innovation enhances decision-making, minimizes stockouts, and boosts customer satisfaction through faster, more reliable service.

Overall, barcode and RFID technologies drive operational excellence, cost savings, and improved competitiveness in today’s dynamic business environment.